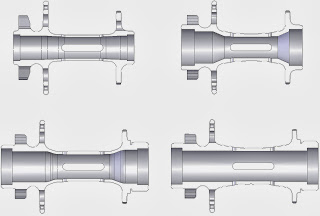

In previous article which shows the k2 hubs, we can see the raw forge is far from the machined part. It is not representative of the forging process. This process allows to have raw parts really close to the finished parts.

Also 3D forging allows to create parts with inner and outer shape from raw forging. This process is perfect to make light and strong stem.